Polyurethane Composite Adhesive

Polyurethane adhesive refers to the adhesive containing carbamate group (-NHCOO-) or isocyanate group (-NCO) in the molecular chain. Polyurethane adhesives are divided into two categories: polyisocyanate and polyurethane.Polyisocyanate molecular chains contain isocyano groups (-NCO) and carbamate groups (-NH-COO-), so polyurethane adhesives exhibit high activity and polarity. It has excellent chemical adhesion to substrates containing active hydrogen, such as porous materials such as foam, plastic, wood, leather, fabric, paper, ceramics, and materials with smooth surfaces such as metal, glass, rubber, and plastic.

Application:

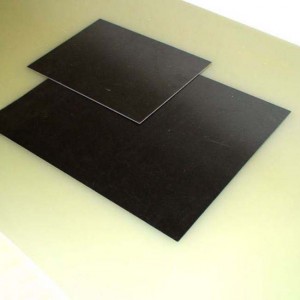

Polyurethane Composite Adhesive can be used for laminating polyester film,polyimide film and non-woven fabric.

Components

|

LH-101BA Hydroxyl component |

LH-101BB Isocyanate component |

|

|

Solid content/% |

30±2 |

60±5 |

|

Viscosity |

40-160S(4# cup,25℃) |

15-150S(4# cup,25℃) |

|

Appearance |

light yellow or yellow transparent liquid |

Colorless or light yellow transparent liquid |

|

Weight ratio |

7-8 |

1 |

|

LH-101FA Hydroxyl component |

LH-101FB Isocyanate component |

|

|

Solid content/% |

30±2 |

60±5 |

|

Viscosity |

40-160S(4# cup,25°C) |

15-150S(4# cup,25°C) |

|

Appearance |

light yellow or yellow transparent liquid |

Colorless or light yellow transparent liquid |

|

Weight ratio |

7-8 |

1 |

|

LH-101HA Hydroxyl component |

LH-101HB Isocyanate component |

|

|

Solid content/% |

30±2 |

60±5 |

|

Viscosity |

40-160S(4# cup,25°C) |

15-150S(4# cup,25°C) |

|

Appearance |

light yellow or yellow transparent liquid |

Colorless or light yellow transparent liquid |

|

Weight ratio |

4-6 |

1 |

Transportation and Storage

Transport: For details, please refer to the relevant safety instructions.

Package: LH-101(B/F/H)A: 16 kg /Tin or 180 kg/Bucket

LH-101(B/F/H)B: 4 kg /Tin or 20 kg/Bucket

Storage: The original packed products should be stored in shady, cool and dry place. The shelf life of LH-101(B/F/H)A is one year and LH-101(B/F/H)B is six months, respectively. The open product must be used within short period of time.

Substrate characteristics

The conditions of film additive, corona treatment, coating, equipment tension and temperature control system are critical importance and will directly or indirectly affect the end use performance for composite products. In mass production, before the actual compound test and proper inspection of the composites were necessary. Due to the actual use conditions of the product are beyond the control of the company. Therefore, the company cannot guarantee the end use.