Description

Surface saver tape,a quality designed tape line with the consistent performance optical laboratories have become accustomed to.

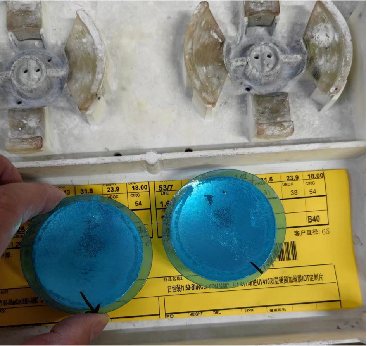

Apply protective film under negative pressure before lens polishing

Because the metal needs to be fixed when the lens is polished, the liquid metal at 58-68℃ is poured on the mold, and it is cooled and solidified at 8-9℃.

The lens enters the polishing machine, after edging, grinding to the required diameter, initial polishing, grinding to the required degree, fine polishing, to ensure smooth surface.During this time the protective film sticks to the metal and remains stable.

Tap the metal to release the lower plate and tear off the protective film.

*Our protective film is not deformed during production, impermeable, moderate adhesion to metal, stable adhesion and easy separation during polishing

Features

Highly conformable to all types of lens styles and base curves:

•High torque resistance

•High clarity: can see clearly through tape for accurate alignment and equipment sensor readings

•Low peel adhesion for clean, easy and effortless tape removal

•Maintains progressive markings for accuracy in alignment, processing,quality inspection and dispensing

•All lens types and base curves are obedient

•Fixed metal alloys in lens processing

•Protects the lens when turning the lens

•Corners are not prone to warping

Data Sheet

| AdhesiveMaterial | Acrylate |

| AdhesiveType | Acrylic/Acrylate |

| BackingMaterial | Polyethylene |

| BlockingType | Alloy-MediumBond |

| Breathable | No |

| Conformability | High |

| FluidResistanceBacking/Carrier | Yes |

| Hypoallergenic | No |

| LinerColor | White |

| LinerMaterial | Paper |

| MaximumLength(Metric) | 46m |

| MaximumWidthCapacity(Metric) | 10.1mm |

| PrintableBacking | No |

| ProductColor | Blue |

| ProductUsage | OpticalLensProcessing |

| Surfacing | Yes |

| TapeColor | Blue |

| TapeTotalCaliper(Metric) | 110.0Micron |

Post time: Jul-10-2023