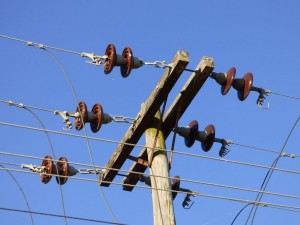

Insulators are special insulation controls that can play an important role in overhead transmission lines. In the early years, insulators were mostly used on utility poles, and gradually developed into high-voltage wire connection towers where many disc-shaped insulators were hung at one end. It was used to increase the creepage distance, usually made of glass or ceramics, and was called an insulator. Insulators play two basic roles in overhead transmission lines, namely supporting wires and preventing current from returning to the ground. These two functions must be guaranteed. Insulators should not fail due to various electromechanical stresses caused by changes in the environment and electrical load conditions. Otherwise, the insulator will not play a significant role, and it will damage the service life and operating life of the entire line.

Insulator: It is an object that fixes and suspends the wire on the tower in an insulated manner. Commonly used insulators for power transmission lines are: disc-shaped porcelain insulators, disc-shaped glass insulators,

Rod suspension composite insulators. (1) Porcelain bottle insulators: domestic porcelain insulators have a high rate of deterioration, need to detect zero values, and have a large maintenance workload.

In the event of lightning strikes and pollution flashovers, string drop accidents are prone to occur, and they have been gradually eliminated. (2) Glass insulator: It has zero self-explosion, but the self-explosion rate is very low (generally a few ten thousandths). No inspection is required for maintenance. In case of self-explosion of the tempered glass parts, the residual mechanical strength will still reach more than 80% of the breaking force, which can still ensure the safe operation of the line. There will be no serial drop accidents in case of lightning strikes and pollution flashovers. It has been widely used in Class I and Class II pollution areas. (3) Composite insulator: It has the advantages of good anti-pollution flashover performance, light weight, high mechanical strength, and less maintenance, and has been widely used in pollution areas of level III and above.

Porcelain insulators: Insulators are commonly known as porcelain bottles, which are insulators used to support wires. Insulators can ensure sufficient insulation for conductors, cross arms and towers. It should be able to withstand the load in the vertical direction of the wire and the tension in the horizontal direction during operation. It also withstands the sun, rain, climate change and chemical corrosion. Therefore, insulators must have both good electrical properties and sufficient mechanical strength. The quality of the insulator is very important to the safe operation of the line. Insulators can be divided into supporting insulators, suspension insulators, anti-pollution insulators and bushing insulators according to their structure. According to the purpose, it can be generally divided into three categories: line insulators, substation support insulators and bushings. According to the material of the insulator. Currently there are porcelain, glass and organic composite insulators. The insulators used in overhead lines are commonly used pin insulators, butterfly insulators, suspension insulators, porcelain cross-arms, rod insulators and tension insulators. There are two types of electrical faults in insulators: flashover and breakdown. Flashover occurs on the surface of the insulator, and burn marks can be seen, but usually the insulation performance is not lost; breakdown occurs inside the insulator, and the discharge occurs through the ceramic body between the iron cap and the iron foot. Insulators may be completely destroyed by arcing. For the breakdown, attention should be paid to checking the discharge traces and burns of the iron feet. In order to prevent dirt such as floating dust from adhering to the surface of the insulator, a path is formed that is broken down by the voltage at both ends of the insulator, that is, creepage. Therefore, the surface distance is increased, that is, the creepage distance, and the distance that is discharged along the insulating surface, that is, the leakage distance, is called the creepage distance.

Creepage distance=surface distance/maximum voltage of the system. According to the degree of pollution, the creepage distance is generally 31 mm/per kilovolt in heavily polluted areas. The voltage can be directly judged according to the number of insulators, generally, 23 for 500kv; 16 for 330kv; 220kv 9; 110kv 5; this is the minimum number, and there will be one or two more. The 500kv transmission line basically uses four-split conductors, that is, there are four for one phase, 220kv uses more than two split conductors, and 110kv uses one more. About 1 insulator is 6-10KV, 3 insulators are 35KV, 60KV lines are not less than 5 pieces, 7 insulators are 110KV, 11 insulators are 220KV, 16 insulators are 330KV; 28 insulators are definitely 500KV. For pin insulators below 35KV, there is no difference in the number of pieces. 10KV overhead lines usually use 10-12m single cement poles and pin insulators. The straight-line distance between the poles is about 70-80m. There is no iron frame for 10KV, just a pole with three high-voltage lines on it. Common in rural areas; 35KV overhead lines usually use 15-meter single or double cement poles (also use a small number of small iron towers, the height is within 15-20 meters) and 2-3 pieces of butterfly insulators, the straight line between poles The distance is about 120 meters; 220KV is definitely a huge iron tower. 220KV overhead lines usually use iron towers over 30 meters and long strings of butterfly insulators. The straight-line distance between iron towers is more than 200 meters. Composite insulators: Ensuring the safe operation of the power system and improving the reliability of power supply is an important indicator for the assessment of power companies, and the continuous use of high-tech materials is an effective way to solve this problem. As a new product, silicone rubber composite insulator has the advantages of light weight, small size, anti-flashover, aging resistance, maintenance-free and maintenance-free, and has been widely used in 35kV and 110kV lines.

Post time: Jan-30-2023