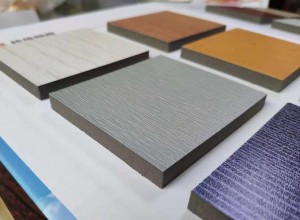

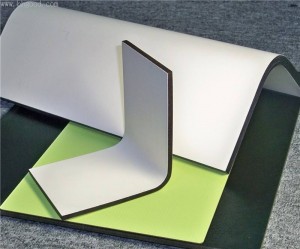

The base material of Compact Laminate Board Phenolic Panel is black, white, light green and brown. It is made of more than 120 sheets of high-quality imported kraft paper impregnated with phenolic resin and imported decorative colored paper with special treatment, and then etched steel plate at 150 high temperature 1430PSI The high-pressure environment suppresses the one-piece decorative material produced by dissolution and irreversible age hardening. The thickness can be adjusted according to the number of kraft papers. The surface color of the anti-fold special board has more than 3,000 patterns and colors to choose from for decoration, and there are 20 three-dimensional surface textures such as matte surface and bright surface.

1. What is compact laminate board? Compact laminate board is a widely used and fashionable low-carbon environmentally friendly material; the inner core of the base material is generally black, and there are various colors such as white and brown, and the surface color is rich in thousands of patterns. More than 20 kinds of three-dimensional surface textures such as matte can meet different decoration needs. It consists of more than 120 pieces of imported high-quality kraft paper impregnated with phenolic resin, imported decorative colored paper with special functions, and then pressed with an etched steel plate in a high-temperature (150) high-pressure (1430psi) environment, which is irreversible after dissolution and 58 minutes One-piece decorative material produced by age hardening.

The thickness can be realized by adjusting the number of kraft papers according to the needs. It can be made from 2mm to 25mm.Compact laminate board has high quality stability, flatness and no deformation, and has functions such as waterproof, fireproof, zero formaldehyde, mildew proof, antibacterial, acid and alkali corrosion resistance, wear resistance, and impact resistance. It is widely used in schools, hospitals, and laboratories. , hotels and airports and other places of all walks of life. 2. Performance of anti-folding special board Anti-folding special board has superior structural functionality and decoration, which are manifested in:

1. Waterproof (boiling water resistance test), moisture-proof, mildew-proof;

2. Resistant to strong acid, strong alkali, and chemical corrosion;

3. Impact resistance, wear resistance, scratch resistance;

4. Antibacterial, easy to clean, with self-cleaning function;

5. Fireproof, heat-resistant, smoke-resistant; anti-static, anti-radiation;

6. Low-carbon and environmentally friendly, non-toxic, tasteless, and formaldehyde-free;

7. Anti-static, anti-radiation; good weather resistance, anti-ultraviolet;

8. Strong stability, smooth and never deformed;

9. The surface is rich and colorful, with three-dimensional patterns.

Third, the color of the anti-fold special board?

The color and surface treatment of anti-fold special board are rich and diverse, and it is gradually developing towards paint-free and three-dimensional, which guides the direction of decorative materials.

4. Compact laminate board is easy to deep process: anti-fold special board does not need edge sealing and other treatments, so it is convenient to process and can shorten the processing time. Anti-fold special board has good mechanical processing performance and physical properties, as well as good resistance to various chemical reagents and non-contamination capabilities. Anti-fold special board manufacturers can directly use standard carbon steel alloy tools for drilling, guiding, cutting, etc. The work can also be drilled by a machine, and the tool can be cut into any desired shape according to the actual design requirements.

5. Compact laminate board products: widely used as hospital wall panels, laboratory countertops, school desks, sports lockers, public bathroom lockers, public health partitions, etc.

Post time: Feb-21-2023