Graphite material is a new type of sealing material, and it is also an important type of sealing material in the industrial industry. It has excellent corrosion resistance, high and low temperature resistance, electromagnetic radiation resistance, small friction factor, self-lubrication, elasticity, and low permeability to liquids and gases.

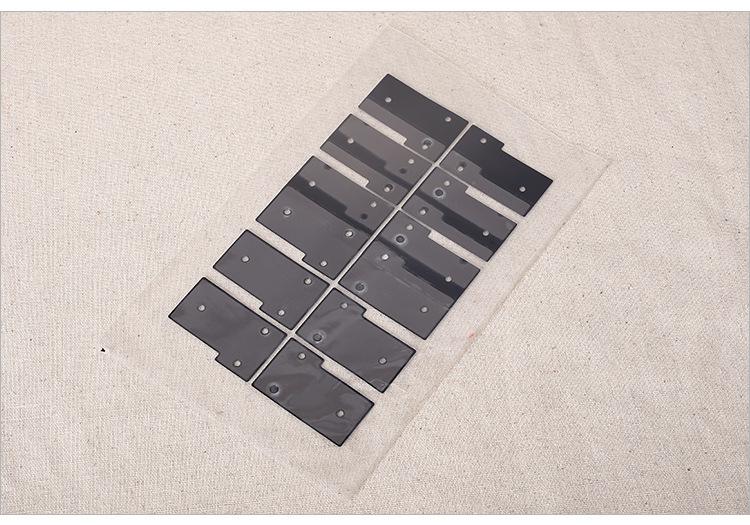

Graphite gaskets can be ground or stamped from pure graphite plates or metal (tooth plates, flat plates, nets) to further strengthen graphite plates according to the same working conditions.

1. Features of flexible graphite gasket:

1. High-purity graphite has good impermeability to gas and liquid, such as a thin plate with a thickness of 0.125mm, the rate of helium is only 2*10-1cm3/s.

2. Good temperature resistance. The temperature of flexible graphite in non-hydrolytic medium is -200~600℃, but it is easy to be oxidized in hydrolytic medium.

3. Anisotropy: The thermal conduction, electrical conductivity and expansion coefficient of flexible graphite have obvious anisotropy.

4. Strong UV resistance.

5. Good corrosion resistance, good chemical stability to general chemical solvents, esters, water vapor, reducing media, etc.

However, there are certain limitations in the hydrolysis medium.

6. Low density, high strength, good softness and resilience.

The scope of application of flexible graphite

Used in industrial pipe flanges, heat exchangers, valve covers, condensers, air amplifiers, exhaust pipes, refrigerators, etc.

Applicable medium: water, steam, oil, acid, alkali, organic solvent, ammonia, hydrogen, etc.

2. Stainless steel further strengthens the graphite gasket

Graphite high-strength gaskets, also known as graphite inorganic gaskets, are made from further reinforced graphite sheet paper strips or ground. The lining material can be the same metal sheet as required. Due to the high mechanical strength of flexible graphite gaskets, it is suitable for gaskets with small diameters, and the further strengthening of graphite gaskets greatly improves the mechanical strength. Excellent properties such as chemical corrosion resistance, electromagnetic radiation resistance, high/low temperature resistance, and long life.

Further enhancements to graphite gasket classification:

1. Carbon steel further strengthens the graphite gasket: the end of the flexible graphite sheet is clamped with a carbon steel strip (0.2mm), and then ground, which strengthens the mechanical strength.

2. 304 stainless steel further strengthens graphite gasket: flexible graphite flakes are attached to both sides of 304 stainless steel, which has extremely high mechanical strength. It is also suitable for various large sizes and complicated shapes, and is also easy to transport. It is also a very popular application field. A wide range of gaskets.

3. 316 stainless steel further strengthens the graphite gasket: it has good corrosion resistance and high temperature strength, but the cost is also lower than other materials.

3. Metal graphite woven into gasket

Metal-graphite woven gaskets are a type of metal-inorganic gaskets woven from metal strips and graphite strips. They are interwoven from V-shaped or W-shaped thin steel strips and fillers. With multi-channel sealing and self-tightening functions, it is not vulnerable to the flaws of the flange pressed into the sealing surface, and it is not NaCl flange sealing surface; it is easy to dismantle, and can partially eliminate the influence of pressure, temperature change and mechanical vibration; it can be used at high temperature and low temperature It maintains excellent sealing performance under various harsh conditions at circulation joints such as , high vacuum, shock and vibration. The metal graphite woven gasket is suitable for the temperature, and the flexible graphite belt is suitable for the temperature -196~650°C (not lower than 450°C in the hydrolysis medium)

Post time: Apr-07-2023