Domestic situation of basalt fiber

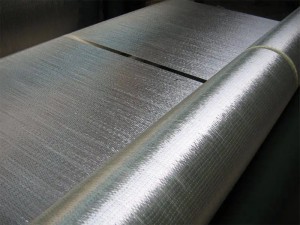

At present, domestic enterprises can produce basalt continuous fiber with the smallest diameter of about 6 microns, and most manufacturers focus on 9-13 micron fibers as their main products. The strength of the original silk is 0.50-0.55N/Tex, which is slightly higher than the alkali-free glass fiber, but the fluctuation is relatively large. According to foreign research data, the strength of basalt fiber can reach more than 3300Mpa, and the converted monofilament strength should be 1.179 N/Tex. It can be seen that under the existing production process conditions, the utilization rate of raw yarn monofilament strength is still relatively low. Therefore, it is necessary to stabilize and improve fiber quality through further technical improvement and standardized management. In addition, basalt fiber has also been tried to be used as a functional material. Through the application practice in recent years, it has been found that the chemical resistance of basalt fiber is relatively stable, but the thermal performance is quite different from the conclusions of previous laboratory studies, and it needs to be re-researched and analyzed.

At present, on the basis of perfecting the 200-hole bushing drawing process, various enterprises have gradually tried 400-hole bushing and multi-socket furnace technology. In addition, the nozzle temperature control and heat exchange nozzle technologies are relatively mature, and the service life of the nozzle is gradually extending, and the service life of the nozzle with 200 holes can basically reach more than 3 months.

At present, the deep processing of basalt fiber products cannot be discussed, and the fiber manufacturers can only rely on the market demand, refer to the glass fiber product production process for product development, and carry out sample production practice in the form of entrusted processing. Some companies do not even have their own special product research and development. team. Therefore, the R&D cycle often cannot be controlled independently, and the R&D results and R&D expectations are far apart, and the effect is greatly reduced.

Sales of basalt fiber and its products

Continuous basalt fiber material is the basic raw material for the production of many different types of materials and downstream products. Basalt fiber can be well combined with other materials or fibers to form many different composite materials. Special attention is worth mentioning continuous basalt fiber composites and carbon fibers, the same basalt fiber can strengthen cement, asphalt concrete and other building components. Continuous basalt composite materials and carbon fiber also have high characteristics, and carbon fiber is a cheaper material than basalt fiber, which can open up a wide application market of basalt and apply it in large quantities in many fields

At present, the application fields of basalt fiber are mainly in the three fields of building structure reinforcement, road traffic and glass fiber reinforced plastics. In recent years, some standards related to basalt fiber have been promulgated and implemented successively, such as “GB/T 23265-2009 Chopped Basalt Fiber for Cement Concrete and Mortar”, “JT/T776-2010 Basalt Fiber and Its Products for Highway Engineering”, etc. It is also mentioned in standards such as “JTG F40-2004 Technical Specifications for Road Asphalt Pavement Construction” and “GB/T 6719-2009 Technical Requirements for Bag Filters”, which laid the foundation for the popularization and promotion of basalt fiber

The characteristics of basalt fiber, such as high strength, high modulus, high temperature resistance, low temperature resistance, and corrosion resistance, make basalt fiber a low-cost substitute for common carbon fiber and an upgraded product of high-grade glass fiber. The market is vast and the application area is large.

The characteristics of basalt fiber, such as high strength, high modulus, high temperature resistance, low temperature resistance, and corrosion resistance, make basalt fiber a low-cost substitute for common carbon fiber and an upgraded product of high-grade glass fiber. The market is vast and the application is large.

Carbon fiber, glass fiber, and basalt fiber are essential raw materials for the composite material industry. Composite materials are widely used in infrastructure, bridges, construction, pipelines, petroleum, wind energy, trains, light rail, subways, automobiles and many more

Basalt fiber is a raw material for composite materials, and only products made with resin are market demand products. The performance and cost performance of basalt fiber can replace carbon fiber and glass fiber to produce products. The production technology, equipment, personnel, and supporting materials of these products are all ready-made, so there is no need to study them again. If you provide materials, existing manufacturers can produce products with better quality than existing products. The door of the vast market has been opened by the glass fiber industry, and basalt fiber products will enter as soon as they go forward

Basalt fiber follow-up products can increase the added value by 300%. Basalt fiber production enterprises should mainly manufacture follow-up products, and sell the rest. A basalt fiber production plant can drive the establishment of more than ten basalt fiber product enterprises in the local area, contributing to the local economic development.

In December 2009, the Key Laboratory of Mineral Resources Research of the Institute of Geology and Geophysics of the Chinese Academy of Sciences reported to the Central Office and the State Office of the “Chinese Academy of Sciences Experts’ Suggestions on Developing a New Resource Economy to Stimulate a New Round of Economic Growth”, which attracted the attention of national leaders. In just one week It has successively received instructions from Vice Premier Li Keqiang and State Councilor Liu Yandong. The “Proposal” lists basalt fiber production technology as a new resource technology, and the production of basalt continuous fiber from basalt is considered to be an important and scarce mineral alternative resource, which can be used to replace steel and aluminum alloys. In addition, on May 27 this year, the Ministry of Industry and Information Technology issued the task of eliminating backward production capacity in China’s industry, which has been greatly improved compared with the past. Among them, it is also involved in the steel, glass, chemical fiber and other industries related to the basalt fiber industry. Therefore, as a new high-performance fiber and a new resource material, basalt fiber will receive more and more attention.

Post time: Jan-03-2023