Thermal conductivity is a measure of a material’s ability to conduct heat. Materials with high thermal conductivity transfer heat efficiently and absorb heat quickly from the environment. Conversely, poor thermal conductors impede heat flow and slowly absorb heat from the environment. According to the S.I (System International) guidelines, the unit of thermal conductivity for materials is Watts per meter Kelvin (W/m•K). The top ten thermally conductive materials and their thermal conductivity measurements are summarized below. Since thermal conductivity varies with the thermal conductivity test equipment used and the measurement environment, these thermal conductivity values are average values.

Top Ten Commonly Used Thermal Conductive Materials

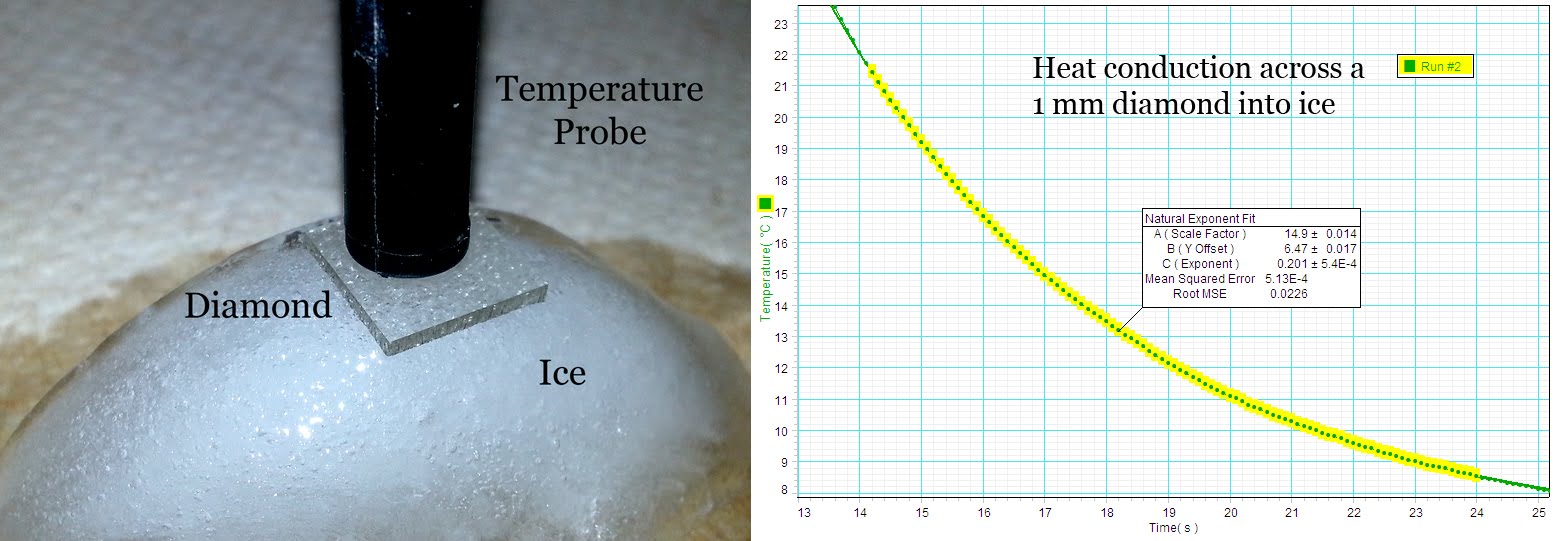

1. Diamond – 2000 ~ 2200 W/m•K

Diamond is one of the most thermally conductive materials, with values five times higher than copper, the most produced metal in the United States. Diamond atoms consist of a simple carbon backbone, an ideal molecular structure for efficient heat transfer. In general, materials with the simplest chemical composition and molecular structure usually have the highest thermal conductivity values. Diamonds are an essential component of many modern hand-held electronic devices. In electronic products, it can promote heat dissipation and protect sensitive parts of computers. Diamond’s high thermal conductivity is also very useful in authenticating gemstones in jewelry. Adding just a small amount of diamond to your tools and techniques can have a huge impact on thermal performance.

2. Silver – 429 W/m•K

Silver is a relatively cheap and abundant conductor of heat. Silver is a material for many utensils and is malleable, making it one of the most versatile metals. 35% of the silver produced in the United States is used in power tools and electronics (US Geological Survey Minerals World 2013). Silver paste, a by-product of silver, is growing in demand due to its use as an environmentally friendly energy alternative. Silver paste can be used to produce photovoltaic cells, which are an important component of solar panels.

3. Copper – 398 W/m•K

In the United States, copper is the most commonly used metal for making heat transfer appliances. Copper has a high melting point and a moderate corrosion rate. And can effectively reduce the energy loss in the heat transfer process. Metal pans, hot water pipes, and car radiators are just a few appliances that take advantage of copper’s heat-conducting properties.

4. Gold – 315 W/m•K

Gold is a rare and precious metal used in specific heat transfer applications. Unlike silver and copper, gold generally does not tarnish and is highly resistant to corrosion.

5. Aluminum nitride – 310 W/m•K

Aluminum nitride is often used as a substitute for beryllium oxide. Unlike beryllium oxide, aluminum nitride does not pose a health hazard in production, but still exhibits similar chemical and physical properties to beryllium oxide. Aluminum nitride is one of the few materials known to be electrically insulating and have high thermal conductivity. Has excellent thermal shock resistance and can be used as an electrical insulator for mechanical chips.

6. Silicon carbide – 270 W/m•K

Silicon carbide is a semiconductor composed of silicon atoms and carbon atoms in balance. A fusion of silicon and carbon, the two combine to create a very hard, durable material. This mixture is commonly used in automotive brakes, components of turbines, and is also commonly used in steelmaking.

7. Aluminum – 247 W/m•K

Aluminum is less expensive and is often used as a substitute for copper. Although not as thermally conductive as copper, aluminum is abundant and has a low melting point, making it easy to process. Aluminum is a key material in the production of LED (Light Emitting Diode) lights. Copper-aluminum hybrids are becoming more popular because they take advantage of the properties of both copper and aluminum and are cheaper to produce.

8. Tungsten – 173 W/m•K

Tungsten has a high melting point and low vapor pressure, making it an ideal material for contacting high current appliances. Tungsten is chemically stable and can be used in the electrodes of electron microscopes without changing the current flow. Also commonly used in light bulbs or as components of cathode ray tubes.

Post time: Jun-14-2023