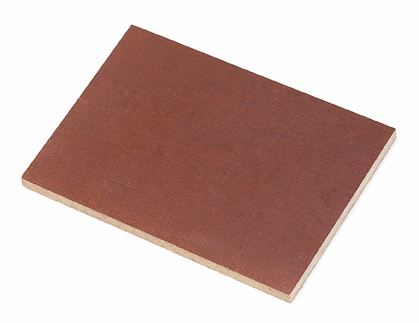

Phenolic resin is also called bakelite, also known as bakelite powder. Originally a colorless (white) or yellowish-brown transparent substance, the market often adds coloring agents to make it appear red, yellow, black, green, brown, blue and other colors, and it is granular and powdery. Resistant to weak acid and weak alkali, it will decompose in case of strong acid and corrode in case of strong alkali. Soluble in acetone, water, alcohol and other organic solvents. It is obtained by polycondensation of phenolic aldehyde or its derivatives. Solid phenolic resin is a yellow, transparent, amorphous blocky substance, reddish due to free phenol, the average specific gravity of the entity is about 1.7, easily soluble in alcohol, insoluble in water, stable to water, weak acid and weak alkali solution. It is a resin made by polycondensation of phenol and formaldehyde under catalyst conditions, neutralization and washing with water. Due to the choice of catalyst, it can be divided into two types: thermosetting and thermoplastic. Phenolic resin has good acid resistance, mechanical properties and heat resistance, and is widely used in anti-corrosion engineering, adhesives, flame retardant materials, grinding wheel manufacturing and other industries.

Phenolic resin powder is a kind of thermoplastic phenolic resin formed by polycondensation of phenol and formaldehyde in acidic medium. It can be dissolved in ethanol and become thermosetting by adding 6-15% urotropine. It can be molded at 150°C and has certain mechanical strength. and electrical insulation properties.

The main feature of phenolic resin is high temperature resistance, and it can maintain its structural integrity and dimensional stability even at very high temperatures. Therefore, phenolic resins are used in high temperature fields, such as refractory materials, friction materials, adhesives and foundry industries.

An important application of phenolic resin is as a binder. Phenolic resins are versatile and compatible with a wide variety of organic and inorganic fillers. Properly designed phenolic resins wet out extremely fast. And after cross-linking, it can provide the required mechanical strength, heat resistance and electrical properties for abrasive tools, refractory materials, friction materials and bakelite.

Water-soluble phenolic resins or alcohol-soluble phenolic resins are used to impregnate paper, cotton cloth, glass, asbestos and other similar substances to provide them with mechanical strength, electrical properties, etc. Typical examples include electrical insulation and mechanical lamination manufacturing, clutch discs and filter paper for automotive filters.

Phenolic resin properties:

High temperature performance: The most important feature of phenolic resin is high temperature resistance, even at very high temperatures, it can maintain its structural integrity and dimensional stability.

Bond strength: An important application of phenolic resin is as a binder. Phenolic resins are versatile and compatible with a wide variety of organic and inorganic fillers.

High carbon residue rate: Under inert gas conditions with a temperature of about 1000°C, phenolic resins will produce high carbon residues, which is conducive to maintaining the structural stability of phenolic resins.

Low smoke and low toxicity: Compared with other resin systems, phenolic resin system has the advantages of low smoke and low toxicity. In the case of combustion, the phenolic resin system produced by scientific formula will slowly decompose to produce hydrogen, hydrocarbons, water vapor and carbon oxides. The smoke produced during the decomposition process is relatively small, and the toxicity is relatively low.

Chemical resistance: Cross-linked phenolic resin can resist the decomposition of any chemical substances. Such as gasoline, petroleum, alcohol, glycol, grease and various hydrocarbons.

Heat treatment: Heat treatment will increase the glass transition temperature of the cured resin, which can further improve the properties of the resin.

Foamability: Phenolic foam is a kind of foam plastic obtained by foaming phenolic resin. Compared with polystyrene foam, polyvinyl chloride foam, polyurethane foam and other materials that dominated the market in the early stage, it has special excellent performance in terms of flame retardancy.

Post time: Apr-17-2023