What is Basalt Fiber?

Basalt fiber is a continuous fiber made of natural basalt rock as the main raw material. After melting at 1450-1500 ℃, it is drawn through a platinum-rhodium alloy drawing bushing at high speed. The color is generally brown and has a metallic luster. It is composed of oxides such as silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide, iron oxide and titanium dioxide. Basalt fiber has many excellent properties such as high strength, electrical insulation, corrosion resistance, high temperature resistance, anti-aging, etc., and it has good compatibility with the environment and does not produce secondary pollution. Therefore, it is a veritable green high-performance new environmental protection material.

my country has listed basalt fiber as one of the four major fibers (carbon fiber, aramid fiber, ultra-high molecular weight polyethylene, basalt fiber) for key development. The needs of aviation and other fields have broad application prospects.

The production process of basalt fiber

The natural basalt rock formed by volcanic eruption is used as raw material, crushed and put into the melting furnace, heated to a molten state of 1450~1500°C, and quickly drawn through a platinum-rhodium alloy wire drawing bushing, and basalt fiber is produced in this way.

In short, the process of making basalt fiber is to “draw” the hard volcanic basalt rock into silk at high temperature.

The diameter of the basalt fiber produced by the existing technology can reach 6~13μm, which is thinner than a hair.

Its production process is shown in the figure below.

Molten Magma

Drawing

As an amorphous inorganic silicate substance, basalt fiber has a short production period, simple process, no industrial waste water and waste gas, and high added value. It is known as the “green new material” in the 21st century.

Excellent performance of basalt fiber

The pure natural continuous basalt fibers are golden in color and appear as smooth cylinders with a perfectly circular cross-section. Basalt fiber has high density and high hardness, so it has excellent wear resistance and tensile strength. Basalt fiber is an amorphous substance, and its service temperature is generally -269~700°C (softening point is 960°C). It is acid and alkali resistant, has strong UV resistance, low hygroscopicity, and good environmental resistance. In addition, it has the advantages of good insulation, high temperature filterability, radiation resistance and good wave permeability, thermal shock stability, environmental cleanliness and excellent ratio of structural performance to structural quality.

Sufficient raw materials

Basalt fiber is made by drawing after melting basalt ore, and the reserves of basalt ore on the earth and the moon are quite objective, and the cost of raw materials is relatively low.

Environmentally Friendly Materials

Basalt ore is a natural material, no boron or other alkali metal oxides are discharged during the production process, so no harmful substances are precipitated in the smoke and dust, and it will not pollute the atmosphere. Moreover, the product has a long service life, so it is a new type of green active environmental protection material with low cost, high performance and ideal cleanliness.

High temperature and water resistance

The operating temperature range of continuous basalt fiber is generally -269~700°C (softening point is 960°C), while that of glass fiber is -60~450°C, and the maximum operating temperature of carbon fiber can only reach 500°C. Especially when the basalt fiber works at 600°C, its strength after fracture can still maintain 80% of its original strength; when it works at 860°C without shrinkage, even the mineral wool with excellent temperature resistance can only maintain at this time the strength after fracture. 50%-60%, the glass wool is completely destroyed. Carbon fiber produces CO and CO2 at about 300°C. Basalt fibers can maintain high strength under the action of hot water at 70 °C, and basalt fibers may lose part of their strength after 1200 h.

Good chemical stability and corrosion resistance

The continuous basalt fiber contains components such as K2O, MgO) and TiO2, and these components are extremely beneficial to improving the chemical corrosion resistance and waterproof performance of the fiber, and play a very important role. Compared with the chemical stability of glass fiber, it has more advantages, especially in alkaline and acidic media. Basalt fiber can also maintain higher resistance in saturated Ca(OH)2 solution and alkaline media such as cement. Alkali corrosion properties.

High modulus of elasticity and tensile strength

The elastic modulus of basalt fiber is: 9100 kg/mm-11000 kg/mm, which is higher than that of alkali-free glass fiber, asbestos, aramid fiber, polypropylene fiber and silicon fiber. The tensile strength of basalt fiber is 3800-4800 MPa, which is higher than that of large-tow carbon fiber, aramid, PBI fiber, steel fiber, boron fiber, and alumina fiber, and is comparable to S glass fiber. Basalt fiber has a density of 2.65-3.00 g/cm3 and a high hardness of 5-9 on the Mohs scale, so it has excellent wear resistance and tensile strength. Its mechanical strength far exceeds that of natural fibers and synthetic fibers, so it is an ideal reinforcement material, and its excellent mechanical properties are at the forefront of the four high-performance fibers.

Excellent sound insulation

Continuous basalt fiber has excellent sound insulation and sound absorption properties. It can be known from the sound absorption coefficient of the fiber at different frequencies that its sound absorption coefficient increases significantly as the frequency increases. For example, if the sound-absorbing material made of basalt fiber with a diameter of 1-3μm (density 15 kg/m3, thickness 30mm) is selected, the fiber will not be damaged under the condition of audio frequency of 100-300 Hz, 400-900 Hz and 1200-7 000 HZ. The sound absorption coefficients of the materials are 0. 05~0.15, 0. 22~0. 75 and 0.85~0.93, respectively.

Outstanding Dielectric Properties

The volume resistivity of continuous basalt fiber is an order of magnitude higher than that of E glass fiber, and it has good dielectric properties. Although basalt ore contains a conductive oxide with a mass fraction of nearly 0.2, after special surface treatment with a special wetting agent, the dielectric loss tangent of the basalt fiber is 50% lower than that of glass fiber, and the volume resistivity of the fiber is also higher than that of glass fiber.

Natural Silicate Compatibility

It has good dispersion with cement and concrete, strong binding force, consistent thermal expansion and contraction coefficient, and good weather resistance.

Low hygroscopicity

The hygroscopicity of basalt fiber is less than 0.1%, which is lower than that of aramid fiber, rock wool and asbestos.

Low thermal conductivity

The thermal conductivity of basalt fiber is 0.031 W/m·K -0.038 W/m·K, which is lower than that of aramid fiber, aluminum silicate fiber, alkali-free glass fiber, rock wool, silicon fiber, carbon fiber and stainless steel.

Compared with other fibers, basalt fiber has excellent performance in many aspects.

|

Item |

Continuous Basalt Fiber |

Carbon Fiber |

Aramid Fiber |

Glass Fiber |

|

Density/(g•cm-3) |

2.6-2.8 |

1.7-2.2 |

1.49 |

2.5-2.6 |

|

Operating Temperature/℃ |

-260~880 |

≤2000 |

≤250 |

-60~350 |

|

Thermal Conductivity/(W/m•K) |

0.031-0.038 |

5-185 |

0.04-0.13 |

0.034-0.040 |

|

Volume Resistance/(Ω•m) |

1×1012 |

2×10-5 |

3×1013 |

1×1011 |

|

Sound Absorption Coefficient /% |

0.9-0.99 |

0.8-0.93 |

||

|

Elastic Modulus/GPa |

79.3-93.1 |

230-600 |

70-140 |

72.5-75.5 |

|

Tensile Strength/MPa |

3000-4840 |

3500-6000 |

2900-3400 |

3100-3800 |

|

Monofilament Diameter/um |

9-25 |

5-10 |

5-15 |

10-30 |

|

Elongation At Break/% |

1.5-3.2 |

1.3-2.0 |

2.8-3.6 |

2.7-3.0 |

Application of basalt fiber

Invisible

Basalt fiber has the characteristics of high strength and high and low temperature resistance, which is very suitable for the surface material requirements of aircraft and missiles. At the same time, it has the characteristics of wave absorption and magnetic permeability, which can realize radar invisibility. So basalt carbon fiber can partially replace carbon fiber for stealth aircraft and missiles.

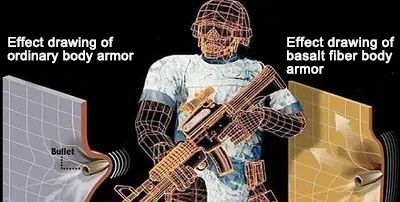

Bulletproof

At present, ultra-high molecular weight polyethylene fibers are usually used for bulletproof vests, which have low heat resistance, and their strength and modulus will decrease under the high-temperature melting of bullets, which will affect the bulletproof effect. In contrast, basalt fiber has strong high temperature resistance, so this problem does not exist.

Aerospace

Basalt fiber has low thermal conductivity and good flame retardancy. The working temperature range is -269°C~700°C, which is resistant to both high and low temperatures. To meet the demanding requirements for materials in the aerospace field, most of Russia’s aerospace materials are made of this material.

Applications in the field of road engineering

Basalt fiber has the advantages of high tensile strength, good mechanical properties, high temperature resistance, UV protection, acid resistance, alkali resistance, salt resistance, and aging resistance. Compared with other fibers, its comprehensive performance is better, and it also meets the requirements for materials in the field of road engineering. Therefore, more and more basalt fiber products have been used in road engineering in recent years.

Heat insulation, temperature resistance, fire protection field

The basalt fiber has the characteristics of high temperature resistance, and can be woven into fireproof cloth, which is used in some fire protection fields. It can also be woven into a high-temperature filter bag for high-temperature filtration and dust removal. In addition, it can also be made into needle felt, which is used in some thermal insulation fields.

Construction sector

Utilizing the excellent corrosion resistance of basalt fiber, it can be compounded with vinyl or epoxy resin through pultrusion, winding and other processes to make a new type of building material. This material has high strength, excellent acid resistance and corrosion resistance, and can be used in civil engineering instead of some steel bars. Moreover, the expansion coefficient of basalt fiber is similar to that of concrete, and there will be no large temperature stress between the two.

Automotive field

Basalt fiber has a stable friction coefficient and can be used in some friction enhancing materials, such as brake pads. Due to the high sound absorption coefficient, it can be used on some interior parts to achieve the effect of sound insulation and noise reduction.

Petrochemical field

The corrosion resistance of basalt fiber gives it unique advantages in the petrochemical field. The common ones are winding high-pressure pipes combined with epoxy resin, which have dual effects of heat preservation and anti-corrosion.

Although basalt fibers still have problems such as large fluctuations in mineral composition, high production costs, and low production efficiency, these problems are both challenges and opportunities for the development and utilization of basalt fibers.

With the breakthrough of domestic basalt fiber drawing technology, the performance of basalt fiber is more stable, the cost is lower, and it has a very broad application prospect.

Post time: Dec-14-2022