High Density Strata Wood for Oil Transformer

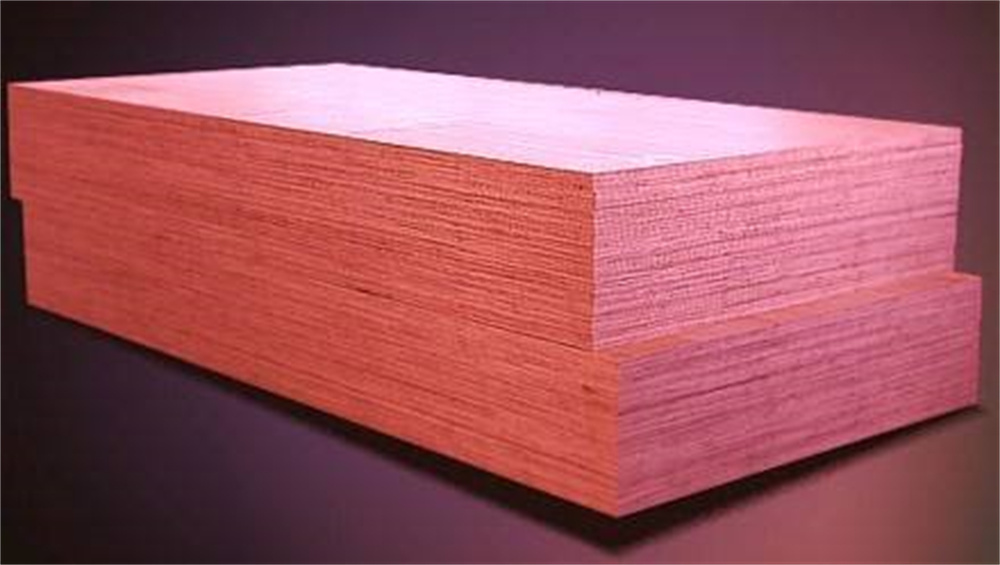

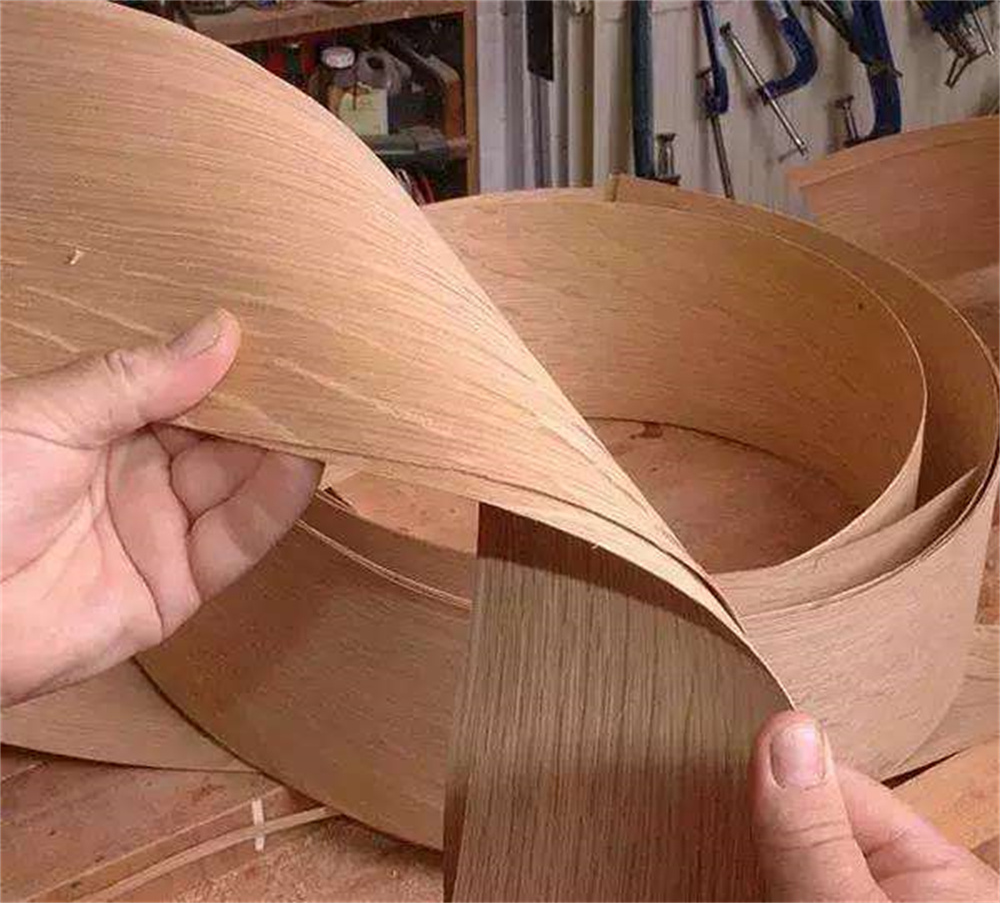

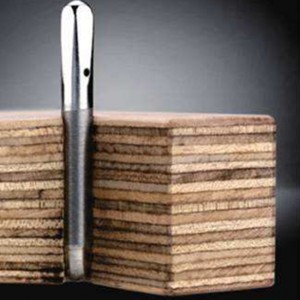

It replaces steel plates, insulating cardboard, epoxy cardboard, etc. The application of epoxy glass cloth board in these aspects reduces the self-weight and material cost of the transformer. Electrical laminated board is a veneer made of high-quality birch wood, which is cooked, peeled and dried. After being coated with special insulating glue, it is made by high temperature and high pressure.

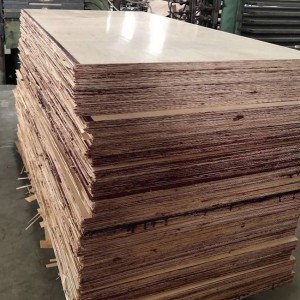

Maximum size of plate (length × width × thickness): 4000×3000×120(mm)

Common specifications and dimensions of plates (length × width × thickness): 3000×1500×(10—120) (mm), 2400×2000×(10—120) (mm)

|

Name |

Electrical insulating laminated wood |

|||||

|

Test item |

Unit |

Test method |

||||

|

Apparent Density |

g/m3 |

IEC 61061-2:2001 |

||||

|

Moisture content |

% |

|||||

|

oil adsorption |

% |

|||||

|

Thickness variation before and after oil absorption |

% |

|||||

|

Compressive strength |

normal |

Vertical to the layers |

Mpa |

Refer to ISO604: 1993 |

||

|

parallel to the layers |

||||||

|

90℃ |

Vertical to the layers |

|||||

|

parallel to the layers |

||||||

|

Flexural strength |

normalcy |

MD |

Mpa |

IEC 61061-2:2001 |

||

|

CD |

||||||

|

90℃ |

MD |

Mpa |

||||

|

CD |

||||||

|

Flexural modulus |

normalcy |

MD |

Mpa |

|||

|

CD |

||||||

|

90℃ |

MD |

|||||

|

CD |

||||||

|

Compressibility perpendicular to the laminations |

C |

% |

||||

|

C rev |

||||||

|

Impact strength parallel to the laminations |

Vertical to the layers |

kj/m2 |

||||

|

parallel to the layers |

||||||

|

Contamination of liquid dielectric |

|

|||||

|

Electric strength perpendicular to the laminations |

MV/m |

|||||

|

Breakdown voltage parallel to the laminations |

KV |

|||||

|

Shrinkage after drying |

A direction |

% |

||||

|

B direction |

||||||

|

thickness |

||||||