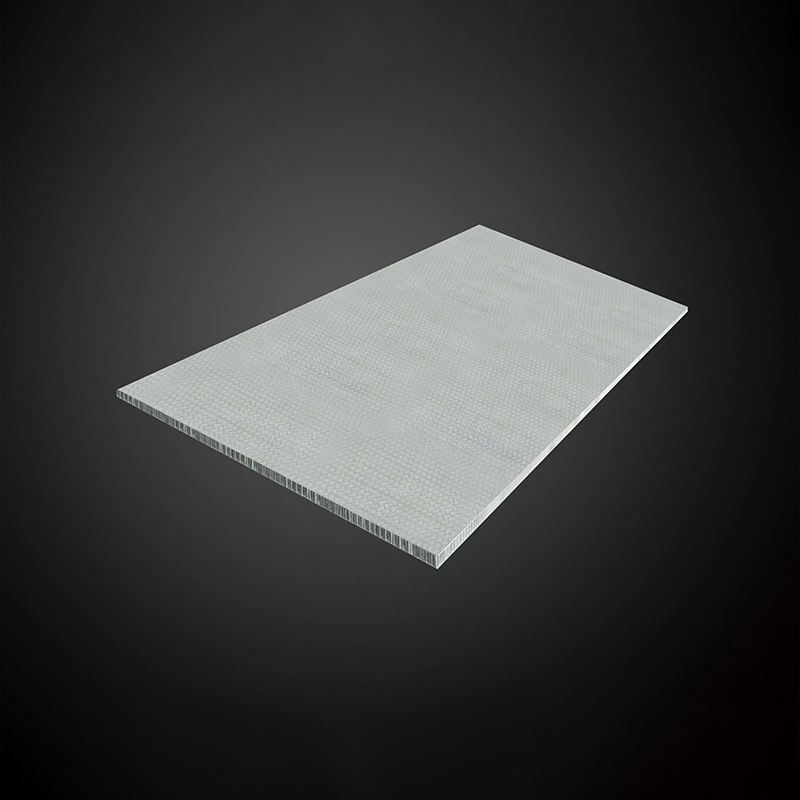

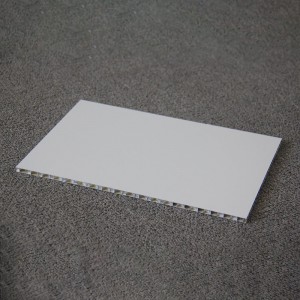

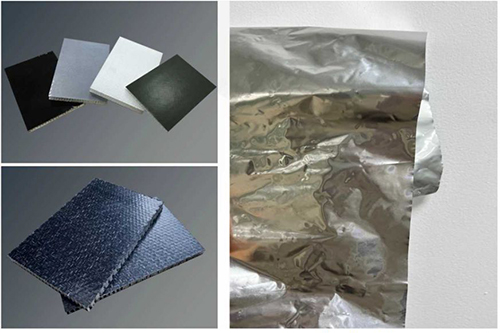

Flame retardant Aluminum honeycomb sandwich panel

* Excellent properties of high wind pressure resistance

* Shock absorption, sound insulation

* Flame retardant, fire rating of B1

* Waterproof, moisture-proof

* No harmful gas release and it is not easy to deform

1. External wall hanging plate of building curtain wall

2. Interior decoration works

3. Billboard

4. Ship building

5. Aviation manufacturing

6. Indoor partition and commodity display stand

7. Commercial transport vehicle and container vehicle body

8. Buses, trains, subways and rail transit vehicles

9. For the modern furniture industry with strict environmental protection requirements, using aluminum honeycomb board as furniture processing materials is a good material choice in the new century. Its completely non-toxic green quality allows furniture manufacturers to reduce unnecessary environmental protection procedures when processing furniture; in addition, aluminum honeycomb board panels can be diversified, such as solid wood, aluminum board, gypsum board and natural marble Honeycomb panel, convenient material selection.

10. Aluminum honeycomb panel partition: the emergence of aluminum honeycomb panel partition breaks the traditional partition mode in the past and has won the market share of medium and high-grade office space with its noble, fresh and elegant style.

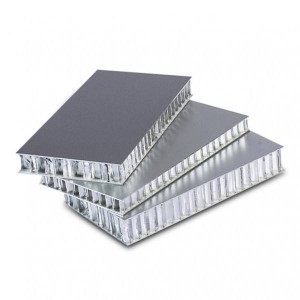

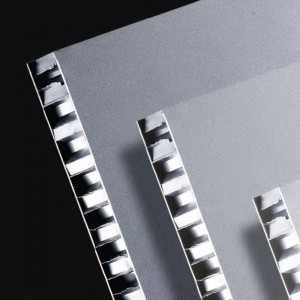

11. It completely overcomes the shortcomings of deformation and middle collapse of other decorative panels when the single area is large. The interconnected aluminum honeycomb core is like countless I-beams. The core layer is distributed and fixed in the whole plate, making the plate more stable. Its wind pressure resistance performance is much higher than that of aluminum plastic plate and aluminum veneer, and has the characteristics of not easy deformation and good flatness, even if the cell size of honeycomb plate is large. It can also achieve extremely high flatness. It is the preferred lightweight material in the construction industry.

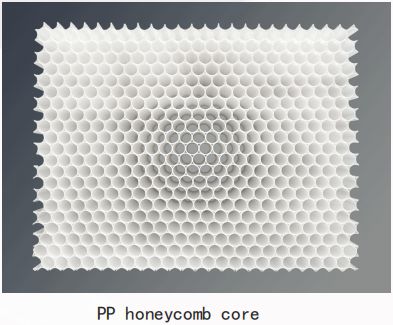

PP honeycomb core: Air-filter, Water saw platform

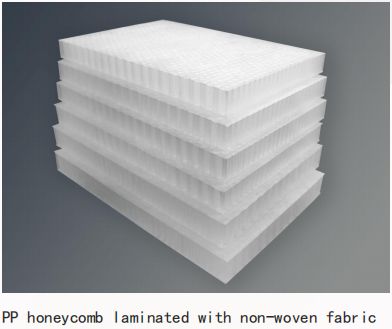

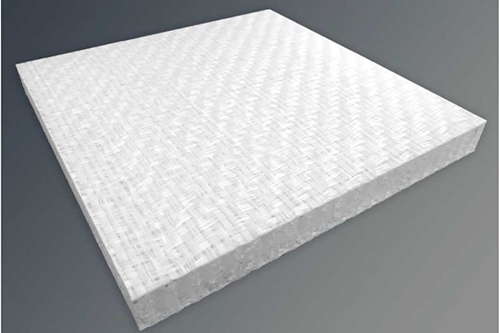

PP honeycomb laminated with non-woven fabric: Core material for sandwich panel

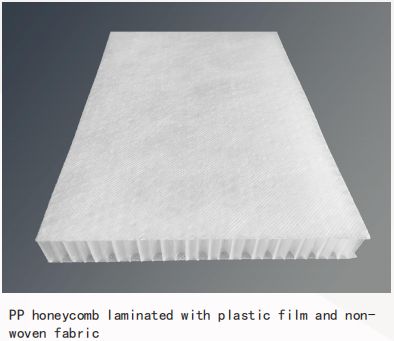

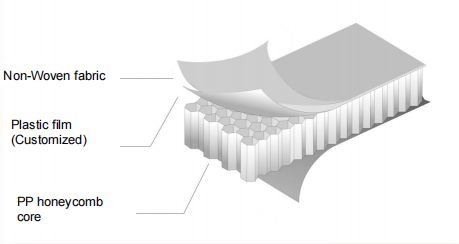

PP honeycomb with plastic film and non-woven fabric: Suitable for RTM process, which can prevent the glue coming into the core

Thickness 0. 1-2. 0mm

Flame retardant: Grade V0 or B1

Surface treatment: Coating Decorating film

All the colors and patterns can be customized

Length Customized, Width cusomized, Thickness 10-100mm.